07-06-2022, 01:54 PM

(This post was last modified: 07-06-2022, 02:03 PM by Tony Betts.)

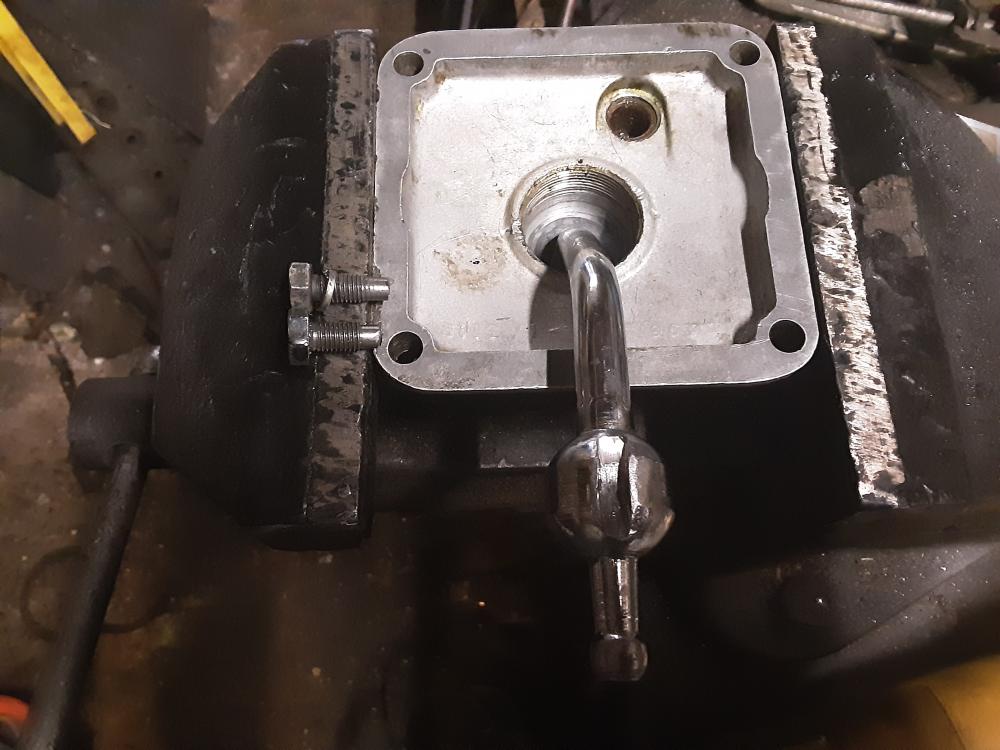

Not the easiest job without a milling cutter.

I've welded and ground the slot, and made a longer peg.

My grinding wasnt 100% accurate, and has pushed the lever slightly toward the driver.

Not a bad thing though.

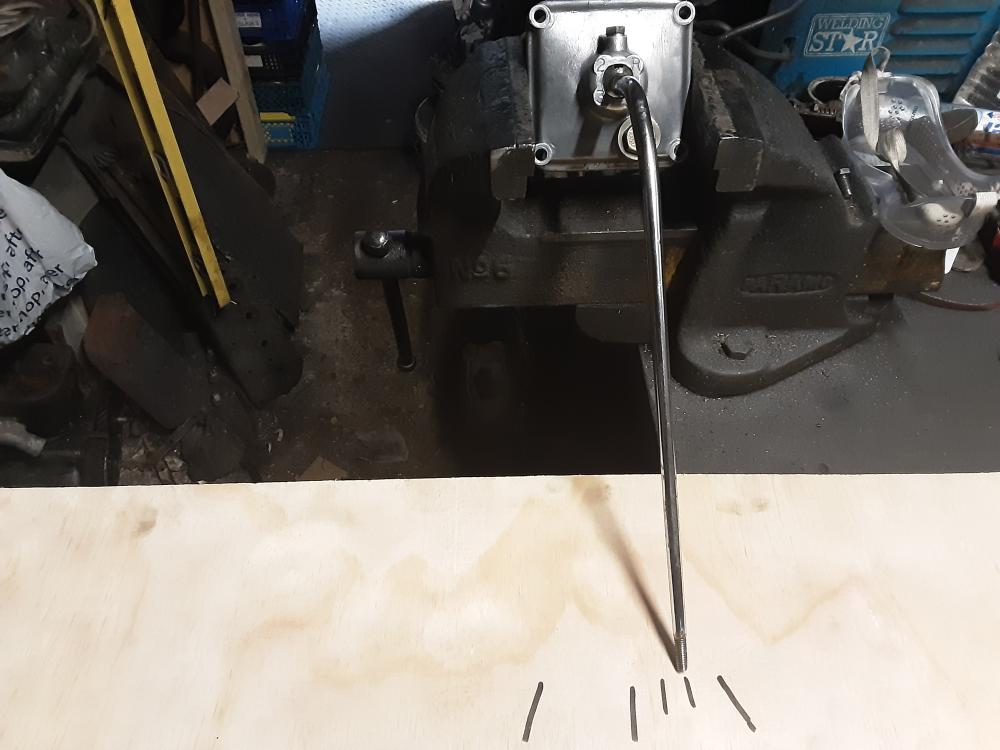

Now it is done, this is how much movement I have.

I've had to lease the ball of to show how little play there is

Just the dynamo and distrib left.

The job I was looking forward to the least.

There is good movement in the rotor arm, so gears could be warn.

Also there is movement between the distrib and dynamo.

I may have to try and find a better dynamo end, this is the bit I dont like. Disterbing a good working dynamo.

I've welded and ground the slot, and made a longer peg.

My grinding wasnt 100% accurate, and has pushed the lever slightly toward the driver.

Not a bad thing though.

Now it is done, this is how much movement I have.

I've had to lease the ball of to show how little play there is

Just the dynamo and distrib left.

The job I was looking forward to the least.

There is good movement in the rotor arm, so gears could be warn.

Also there is movement between the distrib and dynamo.

I may have to try and find a better dynamo end, this is the bit I dont like. Disterbing a good working dynamo.