Joined: Aug 2017 Posts: 3,393 Threads: 106

Reputation:

28

Location: Darkest Bedfordshire

15-06-2024, 12:41 PM

(This post was last modified: 18-06-2024, 07:48 AM by Chris KC.)

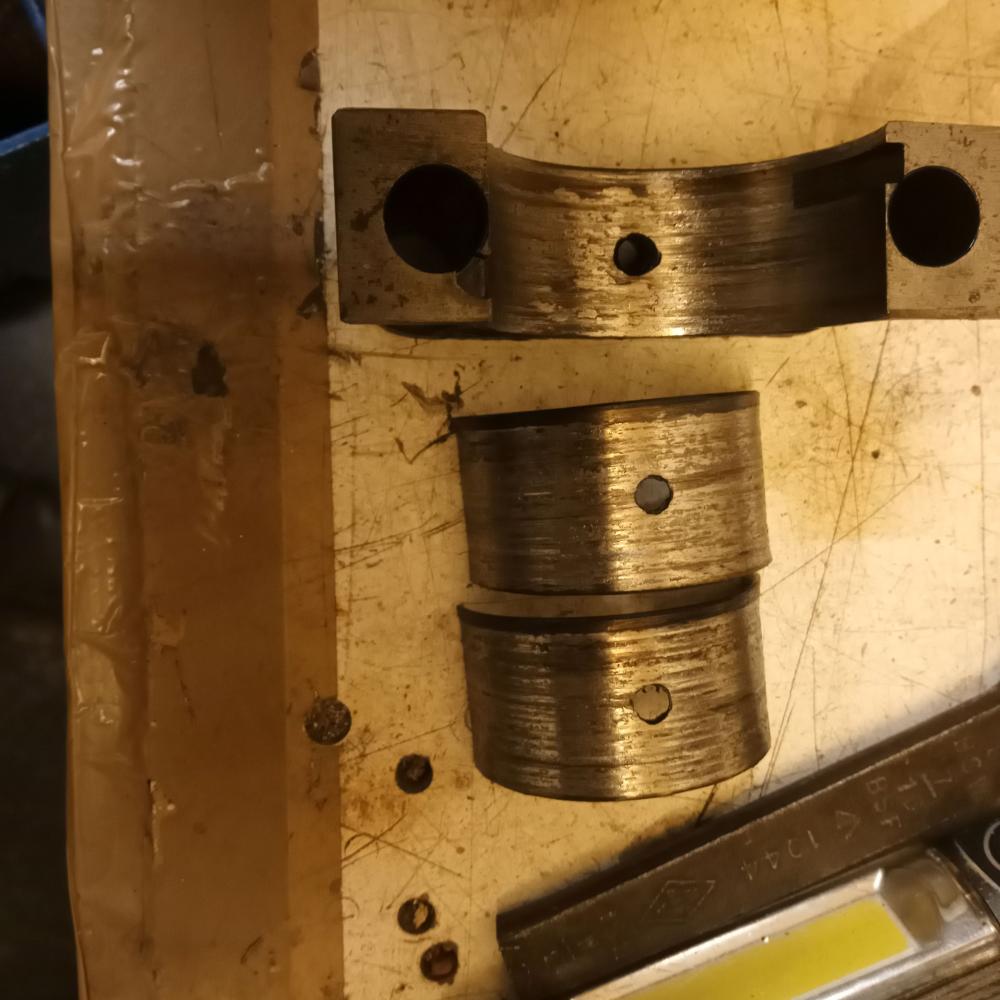

Dave, this looks to me as if the bearing shells have rotated in the housing? - Hard to tell from a photo.

If so, the housing is oversize and the same thing will more than likely happen again with new shells.*

One way would be to fit a "new" (used) housing with less wear.

Unless axial alignment is checked though it's more a matter of "fit and hope" than "fit and forget".

If you want it bulletproof -

Machine a new top housing section about 1 or 2 thou larger diameter than the aluminium casting it fits into (so that it has to be pushed in with a little force). The inner diameter should be left 15 or 20 thou undersize.

Skim the joint face of the lower housing about 10 or 15 thou.

Ideally convert the casing to take bolts from below (then the joint is independent from the block fixing).

Then torque up the housing bolts with the block in position and have it line bored by your local engine recon shop.

Mark parts orientation so they can only go back in the right way...

* p.s. something I've seen before is a well intentioned person line-bored the housing, but failed to appreciate that without a machining allowance you simply end up with an oversize, oval bore... There has to be some metal there (on both sides) to machine.

Joined: Oct 2017 Posts: 1,504 Threads: 54

Reputation:

8

Yes the bearing shells have spun in the housing. My only experience of dealing with this problem is on large 15" journals and there the solution was to fit new under size housings and line bore them.

Joined: Aug 2017 Posts: 3,393 Threads: 106

Reputation:

28

Location: Darkest Bedfordshire

Yes, shell bearings rely on a certain amount of 'nip' or crush occurring when the housing is bolted up to prevent rotation (the lugs are purely for alignment during assembly). If this has not occurred either the housing wasn't done up tight, or it was slightly oversize already. Or conceivably something was trapped in the joint (e.g. misguided insertion of a shim).

A swap for a better s/h housing might do the trick, I'd still check it for alignment though.

There's plenty of meat on the lower housing so it can be re-bored if you machine back the joint face a little - but the upper requires a new part with machining allowance added.

Joined: Aug 2017 Posts: 738 Threads: 13

Reputation:

5

I should have a available three bearing housing in the junk pile.

I will try and find it.

It looks like the shells did not have the locating tabs.

Joined: Aug 2017 Posts: 3,393 Threads: 106

Reputation:

28

Location: Darkest Bedfordshire

The tabs are usually carefully ground or filed off as they don't match the recesses in the housing (obviously they might if you happen to have a serviceable 90-year-old Austin set, otherwise the options are rather limited).

But - I'll say it once more for good measure - the tabs are only for alignment during assembly. It's the "nip" of the housing which stops the shells rotating in service.

Joined: Oct 2017 Posts: 1,504 Threads: 54

Reputation:

8

I'm interested if you find them Dickie, let me know how much they are.

Joined: Oct 2017 Posts: 1,504 Threads: 54

Reputation:

8

Am I correct in thinking that the bearing housing is split at mid height. Each bearing shell is 1/8" short of filling the bottom half housing something I wouldn't expect.

Joined: Aug 2017 Posts: 738 Threads: 13

Reputation:

5

I have just found my complete housing assemby which has tatty 40 thou shells.

it is Upper and lower housing / mounting studs / nuts and lock washer.

I also unearthed a brand new old stock set of Vandervell VP 59 Centre Main Shells

I have not found out what size the VP 59 equates to.

These are available as I have no use for them.