06-12-2022, 03:13 PM

(This post was last modified: 06-12-2022, 03:58 PM by Steve Bryant.)

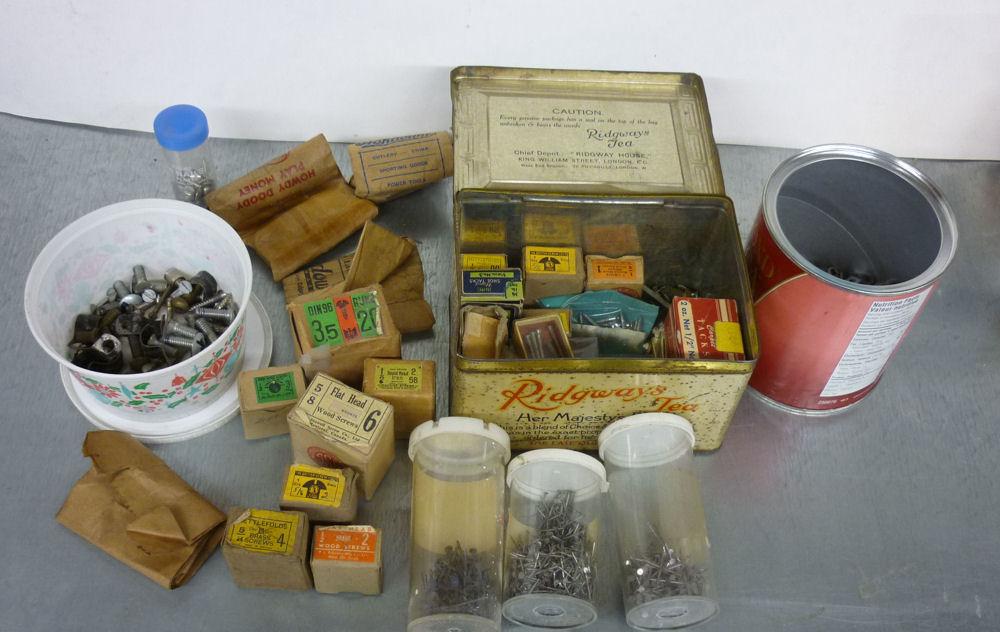

I have been saving bits and fasteners for this build for years. I inherited a lot of assorted screws, brads and finishing nails from my father who had been collecting these from the early fifties. Much of it isn't really useful in the actual build but the large collection of wood screws in brass and steel with slotted heads will be most helpful.

Trying to find anything that looks correct for fasteners here is a exercise in frustration as everything is pretty much Robertson type with just a few exceptions but generally the wrong size or head type.

The plan is to assemble the wood with generic screws and when everything is correct the generic screws will be removed and correct ones inserted.

Cheers,

Stephen

I'm so thankful to have a warm place to do the build. The temperature outside today is -21C which makes for difficult or impossible to work in a unheated shop or garage.

Stephen

Trying to find anything that looks correct for fasteners here is a exercise in frustration as everything is pretty much Robertson type with just a few exceptions but generally the wrong size or head type.

The plan is to assemble the wood with generic screws and when everything is correct the generic screws will be removed and correct ones inserted.

Cheers,

Stephen

I'm so thankful to have a warm place to do the build. The temperature outside today is -21C which makes for difficult or impossible to work in a unheated shop or garage.

Stephen