26-08-2024, 07:37 PM

Following on from my 'what have you done' post where we were trailered home following what I suspected was a head gasket failure, here's what happened next. Appreciate it is an old story for most experienced hands but I am pleased to have (hopefully) discovered the cause and it might be interesting for some as such failures are usually spoken about in relation to the condition of the block, either surface or cracks etc.

The head gasket last failled only 3000 miles ago, albeit it was 6 years ago as, due to a house move and 2 1/2 years of restorations where I have had to learn how to plaster, install stairs, kitrchens etc I haven't had much time for jaunts, the old girl was also sitting about 300 miles away from me for much of the time.

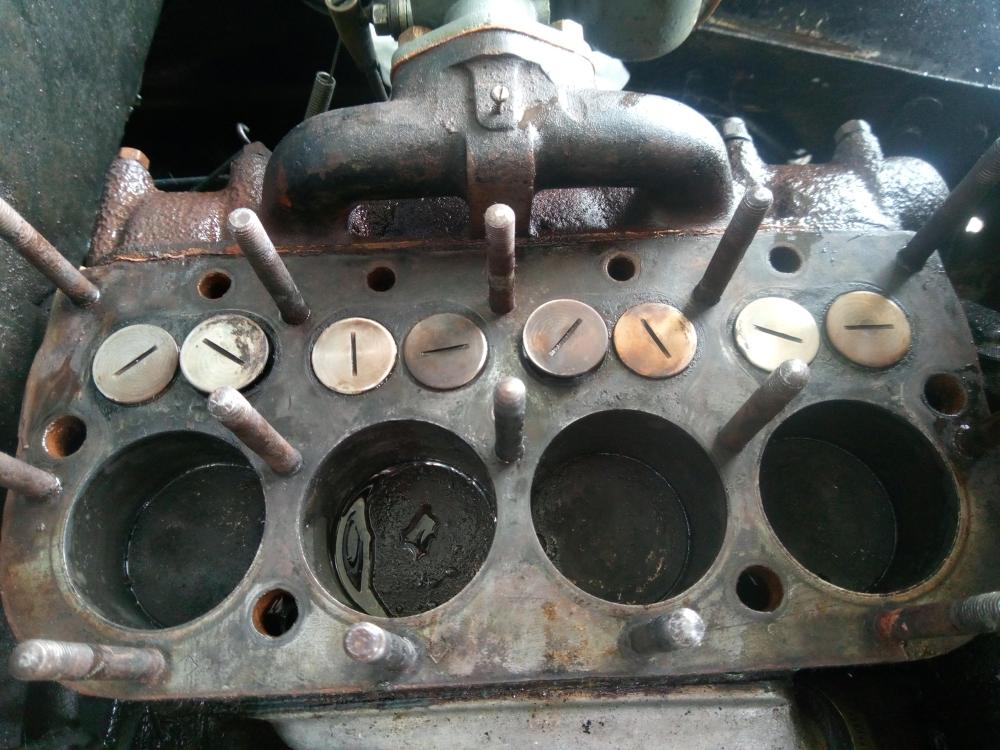

Anyway, head off this morning and as you can see the gasket had blown straight between 2 and 3.

A clean up and the block seemed to me to be relatively OK. No cracks, damage etc.

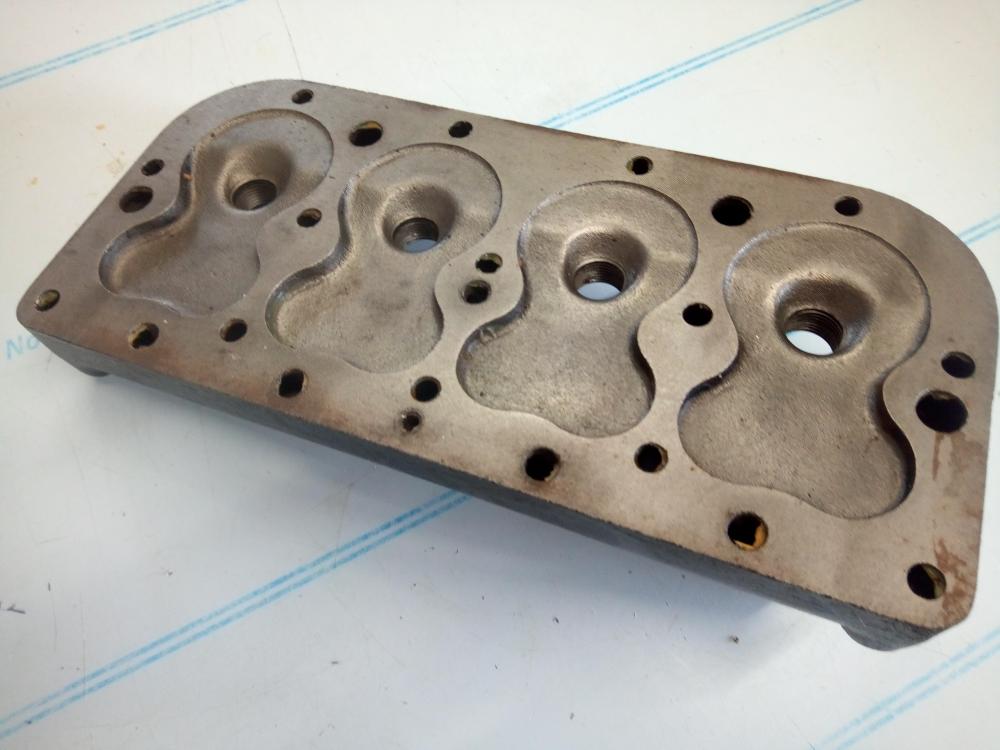

A close look at the head and you can see that the witness marks from the edge of the gasket are missing from the area where the gasket failed.

Then a bright light and a steel ruler revealed daylight from a depression in the head.

Luckily I have a nice ground head bought a few years back from the much missed Dave Orange.

Tomorrow it all goes back together.

So, any suggestions for someone I could send the failed head to for a skim, ideally North East?

Thanks

Andy

The head gasket last failled only 3000 miles ago, albeit it was 6 years ago as, due to a house move and 2 1/2 years of restorations where I have had to learn how to plaster, install stairs, kitrchens etc I haven't had much time for jaunts, the old girl was also sitting about 300 miles away from me for much of the time.

Anyway, head off this morning and as you can see the gasket had blown straight between 2 and 3.

A clean up and the block seemed to me to be relatively OK. No cracks, damage etc.

A close look at the head and you can see that the witness marks from the edge of the gasket are missing from the area where the gasket failed.

Then a bright light and a steel ruler revealed daylight from a depression in the head.

Luckily I have a nice ground head bought a few years back from the much missed Dave Orange.

Tomorrow it all goes back together.

So, any suggestions for someone I could send the failed head to for a skim, ideally North East?

Thanks

Andy

Enjoy yourself, it's later than you think!