23-04-2020, 12:52 PM

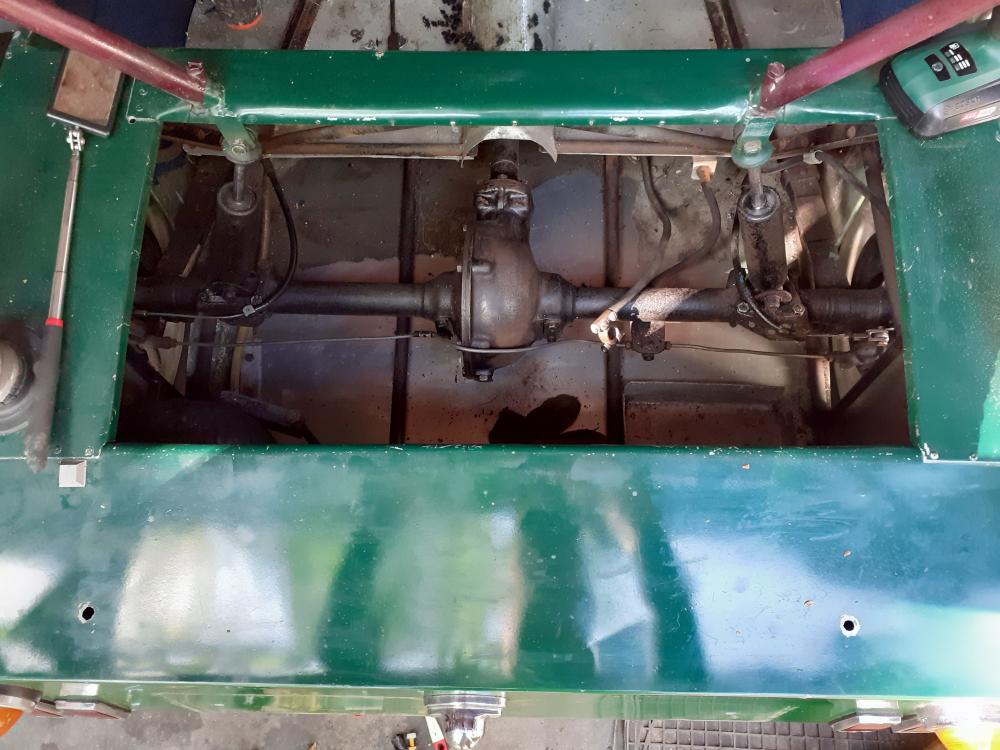

Starting to uncover how to get to the oily bits which need maintenance. Pop rivets everywhere and I now find that the floor is riveted from the underside, upwards, to the frame for the rear suspension, which in inconveniently just where I'd like to get the seat lower.

I'm wondering about cutting the floor from above to expose the spring to see if replacement/taking out is possible with access entirely from above. Ian Clayton's former car just had the undertray as its floor, with the chassis exposed in the cabin.

Some of the frame which is bolted to the floor is welded into the roll bar structure. but could some of it go, perhaps?

The rear axle is dated 2.34 but NO marks below the date signifying ratio or serial number. Has anyone come across this on a D Axle before? There is also a '2' stamp on the top of the connection to the pinion/TTube section. Wondering if the chassis could have Nippy routes but haven't got to the crossmember ends yet.

I'm wondering about cutting the floor from above to expose the spring to see if replacement/taking out is possible with access entirely from above. Ian Clayton's former car just had the undertray as its floor, with the chassis exposed in the cabin.

Some of the frame which is bolted to the floor is welded into the roll bar structure. but could some of it go, perhaps?

The rear axle is dated 2.34 but NO marks below the date signifying ratio or serial number. Has anyone come across this on a D Axle before? There is also a '2' stamp on the top of the connection to the pinion/TTube section. Wondering if the chassis could have Nippy routes but haven't got to the crossmember ends yet.