07-04-2020, 10:13 AM

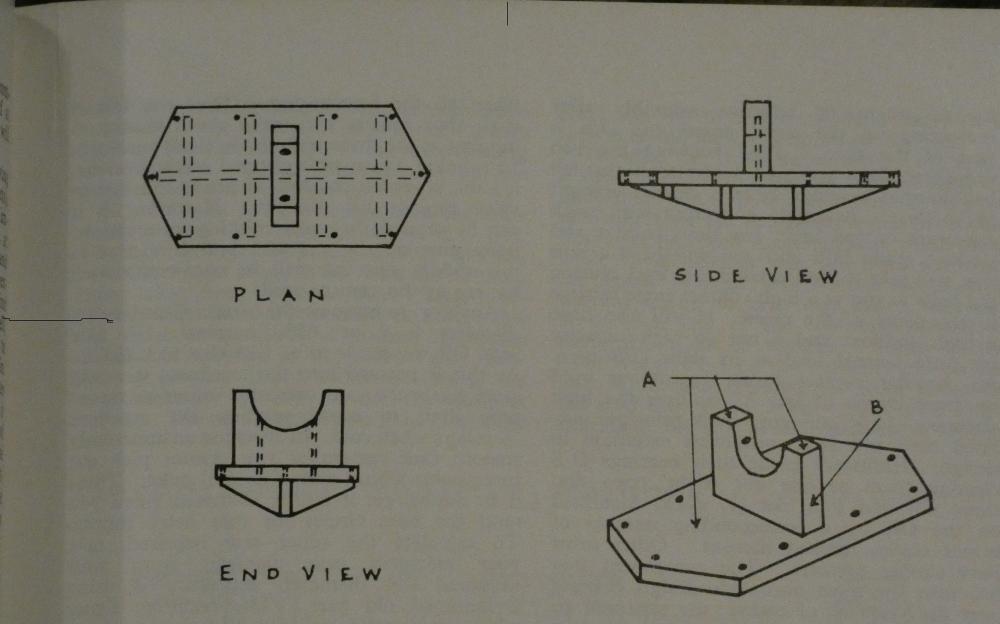

Jamie was enquiring about Jack Cottons modification of the three-bearing engines crankcase to stiffen it so that the centre main bearing stays in alignment with the other two main bearings.

The three-bearing engine was chosen so that high revs could be achieved without running the big-ends which Jack found was a problem with the (pre-Phoenix) 1 5/16" two-bearing, jet-lubricated, crankshaft.

The diagram comes from the 750MC's 1966 publication "Design for Competition" which is the precursor of the "Companion".

Did many people try this modification in the Formula days?

Is Jack Cotton the famous UK politician?

The aluminium casting also reinforced the centre main bearing housing which, as Bob Culver pointed out, is not well supported.

Jack Cotton listed the machining needed on the crankcase and the casting - lots of tricky milling needed.

The three-bearing engine was chosen so that high revs could be achieved without running the big-ends which Jack found was a problem with the (pre-Phoenix) 1 5/16" two-bearing, jet-lubricated, crankshaft.

The diagram comes from the 750MC's 1966 publication "Design for Competition" which is the precursor of the "Companion".

Did many people try this modification in the Formula days?

Is Jack Cotton the famous UK politician?

The aluminium casting also reinforced the centre main bearing housing which, as Bob Culver pointed out, is not well supported.

Jack Cotton listed the machining needed on the crankcase and the casting - lots of tricky milling needed.