02-05-2019, 11:22 PM

Ian was discussing hamer forms on the forum the other day, I have just used a similar approach to make the access panel for the off side rear brake adjuster.

I firstly make two essentially identical MDF profiles one of which is fitted to a base plate. From a piece of scrap hardwood, in this instance from an old piece of mahogany I liberated from a builders bonfire, I made the former I wanted to hammer into the MDF profiles, between which I sandwich and clamp the aluminium sheet. The former is then quite brutaly hammered into the metal.

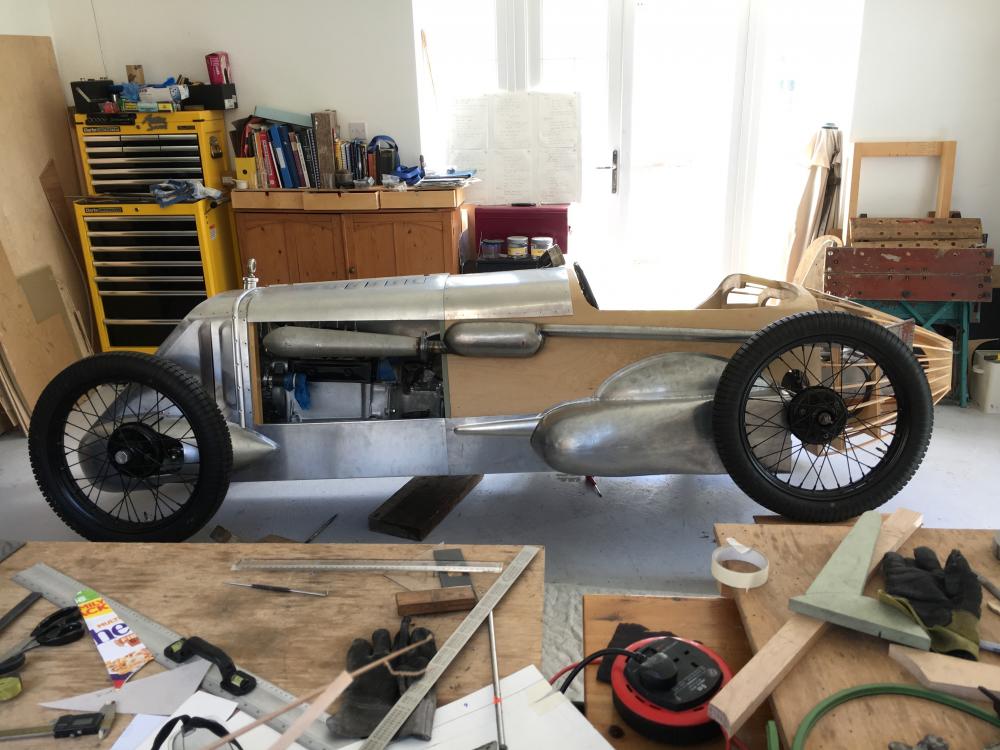

The new panel is then offered up to the car for trimming and marking up of the lower flange

Once the trimming is complete and the flanges are created, the attachment holes are punched into the metal, then it is screwed in place

I used a 1000 series metal for this component and no annealing was required.

Regards, Mark.

I firstly make two essentially identical MDF profiles one of which is fitted to a base plate. From a piece of scrap hardwood, in this instance from an old piece of mahogany I liberated from a builders bonfire, I made the former I wanted to hammer into the MDF profiles, between which I sandwich and clamp the aluminium sheet. The former is then quite brutaly hammered into the metal.

The new panel is then offered up to the car for trimming and marking up of the lower flange

Once the trimming is complete and the flanges are created, the attachment holes are punched into the metal, then it is screwed in place

I used a 1000 series metal for this component and no annealing was required.

Regards, Mark.