Joined: Aug 2017 Posts: 558 Threads: 89

Reputation:

7

Location: Deepest darkest Kent

That's going to be a screamer.

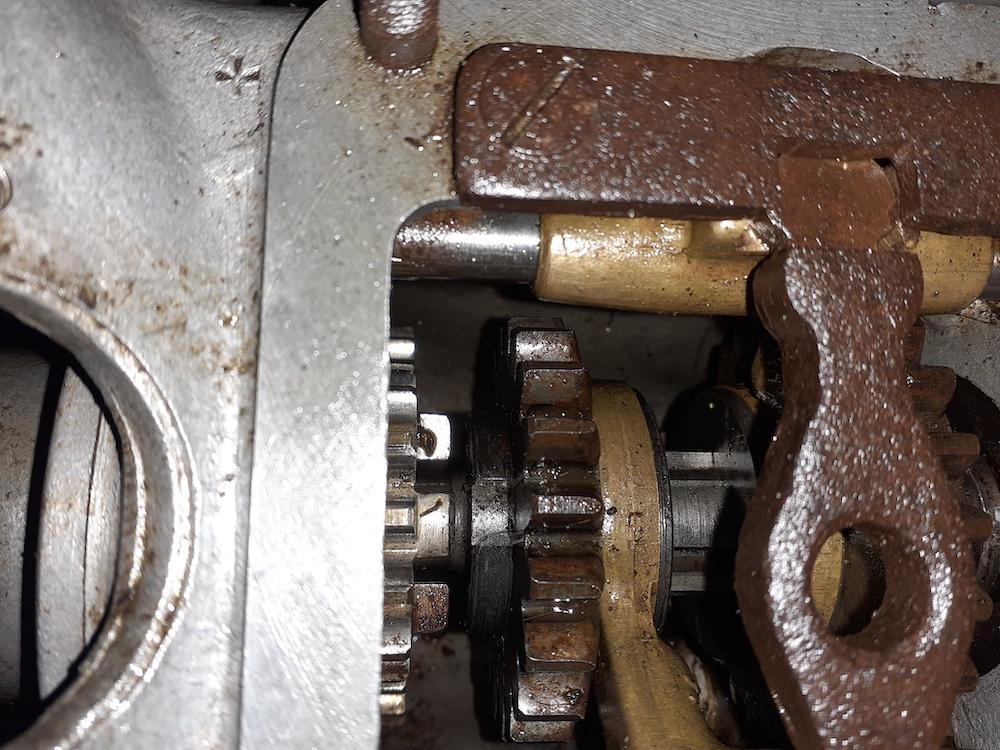

Worn and pitted second gear just for a start.

Joined: Aug 2017 Posts: 3,329 Threads: 372

Reputation:

16

Car type:

great, Robert. I scrutinise those surfaces now and see. I'll take apart and follow Howard's lead!

Joined: Aug 2017 Posts: 558 Threads: 89

Reputation:

7

Location: Deepest darkest Kent

Jon,

I took seven gearboxes apart when I was building my Ulster rep. Cleaned everything and inspected. In the end I was able to build three boxes.

Some of gears looked like they had been in the harbour.

Joined: Aug 2017 Posts: 899 Threads: 50

Reputation:

4

Location: North Wiltshire

Car type: 1927 Chummy, 1938 Big Seven 1/2 a Trials Chummy

08-12-2021, 11:31 AM

(This post was last modified: 08-12-2021, 11:34 AM by Parazine.)

I've done quite a few gearboxes over the years. With three speed boxes, the critical thing is the state of the teeth on 1st and 2nd gear; they can be extremely worn and misshapen. The situation is better if you fit an "Andes" 2nd gear pair from Andy Bird, but the 1st pair can be pretty poor as well. Most of the other wearing bits are either replaceable or repairable. One point which is difficult is the roller bearing concealed in the nose piece. This runs on the 1st motion shaft, with an outer race pressed into the ally housing. The outer race is unobtainable, the 1st motion shaft can be repaired but it's expensive. The rollers should be available although I haven't tried recently.

Your box looks pretty good as far as tooth wear and shape goes, the gears just need a brisk wire brush or a run through the electrolytic de-rust bath. In order to do this, the box really needs stripping and proper cleaning, new bearings, careful re-assembly and set-up.

Robert, doubt it's going to be a screamer, that needs the gears to be worn out of shape. All three speed boxes make some noise!

Joined: Aug 2017 Posts: 1,230 Threads: 33

Reputation:

7

Location: Salop

Car type: '28 GE Cup. '28 AD Chummy '30 RL Saloon. '34 RP Saloon. Too Many toys!

08-12-2021, 12:41 PM

(This post was last modified: 08-12-2021, 06:20 PM by Hedd_Jones.)

Jon

It all depends on what you propose to do with the box. And what level of perfection you are striving for.

If its going in a nice car, particular one with a roof on it, a quieter box is nicer. And Robert has the answer Take it to bits, assess it and sort it 100% gears and all.

However my other hobbies include messing with historic vehicles where you cant take 7 gearboxes apart to build a good one. Indeed there may not be 7 gearboxes in the world, only the nasty rusty one on the bench. Generally the rust and pitting to the gears is less an issue than shaft and bearing wear, and the latter are generally easily and/or relatively cheaply repaired. Significantly more beer vouchers are required for gears. My view is disassembled, assessed and reassembled with replacement bearings/shafts as necessary it'll be fine. cheap rebuild too given last time I did it all that sort of stuff was available.

In an open car, used infrequently, is it worth fitting it, fill it with oil. Change the oil a couple of times in the early use of the box and see how it goes?. Particularly on a low horsepower road car. You've clearly concluded that there are no fundamental defects. And these boxes are very robust indeed. With the amount of time I have to spend on my cars, this would be my option No1. Those who strive perfection would no doubt be surprised how often all is well.

If its on the shelf as a spare, either as a short term fit while you rebuild the failed one, or to rebuild upon failure of the main one. you've stopped any deterioration. Put it on the shelf.

Joined: Aug 2017 Posts: 3,329 Threads: 372

Reputation:

16

Car type:

ok, well this gives me options. I like Robert's learning from comparison (and I find I can't learn unless I do). I HAVE a decent box to fit in first, and that's got Vince's Andes gears c/o the previous owner who never got around to fitting it. So I can compare noise against this one and then pull apart if necessary. Are they best stored with oil in?, accepting that that is a bit inconvenient if you dont have spare tops.

Joined: Aug 2017 Posts: 498 Threads: 15

Reputation:

9

Location: Dunchurch, Warwickshire

I would put oil in it to store it, fit a cardboard lid and store it upright.

.

.