Joined: Aug 2017 Posts: 3,329 Threads: 372

Reputation:

16

Car type:

I'm just drilling to tap an old 1/4 stud out of the centre manifold position. Its right below a smaller water channel junction into the head (why so small out of interest?) but I've drilled and at present can see there is head stud beyond.. but no apparent pathway for water anywhere. What is best practice here - do I need to remove the head stud too in order to see passage beyond?

Whilst sorting tap to do this, came across one marked "A Nr.2" (that's it) Its about 4.4mm. Do I take it that this could be 2BA? Or something more weird? Its very fine of thread, but no marking to say.

Joined: Aug 2017 Posts: 1,715 Threads: 47

Reputation:

25

Location: Auckland NZ

Car type: 36 Nippy, 31 RM, 38 Special, 24 Works Rep

Why so small, I guess they were limited for space, but it is this area between two exhaust posts that the blocks need cooling, and part of the reason, I believe, some crack especially when combined with over tightened head studs. The water way's around the exhaust ports is very small and very often seriously clogged with corrosion, a problem which is made worse by owners fitting studs where the treaded portion is too long. I have sectioned a couple of scrap blocks to see how the water passages work, once you can see it becomes easier to clear the accumulated detritus with various picks, rods, drills and modified hacksaw blades, yes removing the adjacent head stud helps this quest. Unfortunately I don't have any picture of the blocks I sectioned that I can post on here to help you Jon, the blocks have been in storage in Auckland since have moved to Wellington.

Black Art Enthusiast

Joined: Aug 2017 Posts: 1,751 Threads: 43

Reputation:

15

Location: Malvern, Victoria, Australia

(22-11-2021, 09:57 PM)Ian Williams Wrote: Why so small, I guess they were limited for space, but it is this area between two exhaust posts that the blocks need cooling, and part of the reason, I believe, some crack especially when combined with over tightened head studs. The water way's around the exhaust ports is very small and very often seriously clogged with corrosion, a problem which is made worse by owners fitting studs where the threaded portion is too long. I have sectioned a couple of scrap blocks to see how the water passages work, once you can see it becomes easier to clear the accumulated detritus with various picks, rods, drills and modified hacksaw blades, yes removing the adjacent head stud helps this quest. Unfortunately I don't have any picture of the blocks I sectioned that I can post on here to help you Jon, the blocks have been in storage in Auckland since have moved to Wellington.

Hence the suggestion to drill out the core plug about 2 o'clock to the front welch plug and clean out the waterways, putting in a threaded plug to facilitate future cleanouts.

Joined: Aug 2017 Posts: 3,329 Threads: 372

Reputation:

16

Car type:

Tony - this plug not on all though, correct? I don't seem to have it on this block. Could it be worth creating tapping a port on ones without?

Ian, I'll remove that centre front head stud and investigate further.

Joined: Aug 2017 Posts: 1,715 Threads: 47

Reputation:

25

Location: Auckland NZ

Car type: 36 Nippy, 31 RM, 38 Special, 24 Works Rep

Jon, if you have a good probe around you can get a rod through the side water manifold between bore 3 and 4 up through and into the water passage Tony mentions. It is really difficult to describe the shape of the water passages in this area and a picture and would help you enormously. Have you used a rust removal chemical in the water jacket, this will help to dislodge and dissolve crud in there.

Black Art Enthusiast

Joined: Aug 2017 Posts: 1,751 Threads: 43

Reputation:

15

Location: Malvern, Victoria, Australia

(23-11-2021, 12:38 PM)JonE Wrote: Tony - this plug not on all though, correct? I don't seem to have it on this block. Could it be worth creating tapping a port on ones without?

Ian, I'll remove that centre front head stud and investigate further.

Yes Jon, the later blocks don't have the 'plug' so you need to drill and tap in the same area- probably check an early block for the best location.

Joined: Aug 2017 Posts: 3,329 Threads: 372

Reputation:

16

Car type:

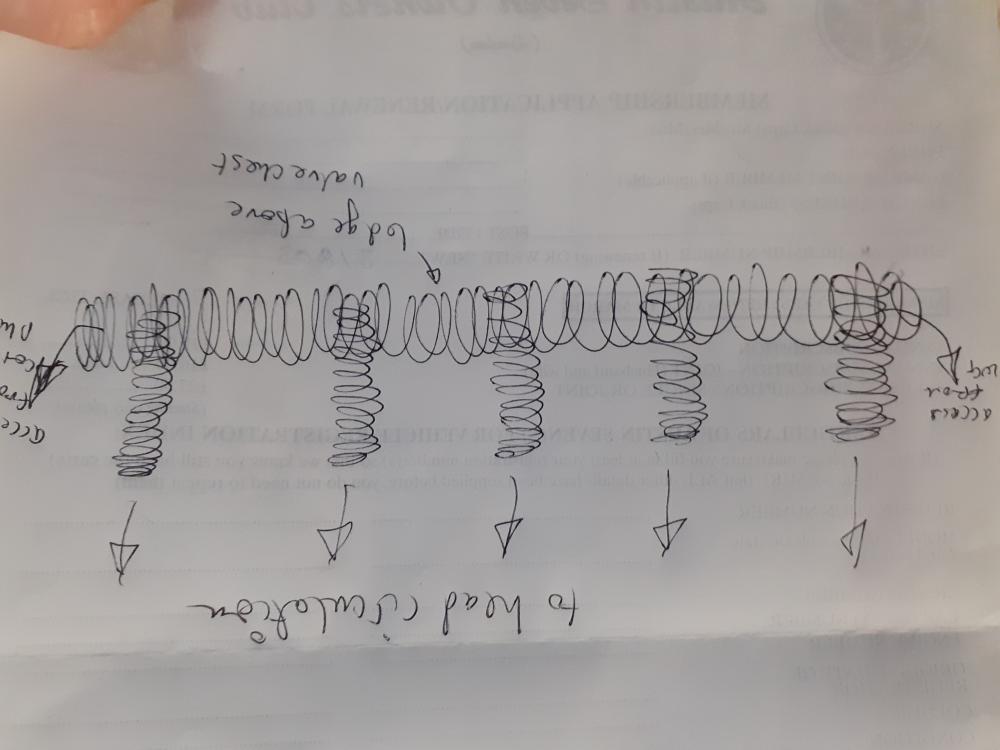

further inspection shows that all the vertical water 'wells' in the block go down to within 1cm of the top of the valve chest. The ominous centre one does not, so I'm intending pillar drilling down to clear the obstruction. At present, I'm imagining the water jacket in this "shelf" over the top of the valve chest as having the characteristics of perhaps an inch high, and perhaps 1/8" thick, and running the length. Or following Ian's comments and others' findings, is it more complex?

Joined: Aug 2017 Posts: 3,329 Threads: 372

Reputation:

16

Car type:

24-11-2021, 05:02 PM

(This post was last modified: 24-11-2021, 05:05 PM by JonE.)

ok, well I'd forgotten about the inlets and the outlets! This appears to be the flow, and you can get a wire along from each core plug entrance to mid way along toward the centre. I've decided to acid treat just this area by blocking off all the manifold stud holes and back row of entrances into the cylinder head circulation, and then will create an acid bath there just in the pictured bits, block N/S downward.

I found the shaft beneath the centre position (the little hole, N/S) completely blocked underneath the manifold stud, and also found that there didn't appear to be any connection with the nearest head stud to that little hole centre N/S.

Can anyone add to this from their own excavations?

note, I've put this image in twice now and it goes this way up even when I rotate it 180 degrees to correct the anomoly, before uploading. So you will have to live with it!

Joined: Aug 2017 Posts: 1,035 Threads: 54

Reputation:

5

Location: The delightful town of Knaresborough, North Yorkshire

This should show it the right way up.

|