AG Wood writes:

"I noticed in the above forum thread that some of the contributors were experiencing difficulty retaining the brake linings on the brake shoes during the riveting operation.

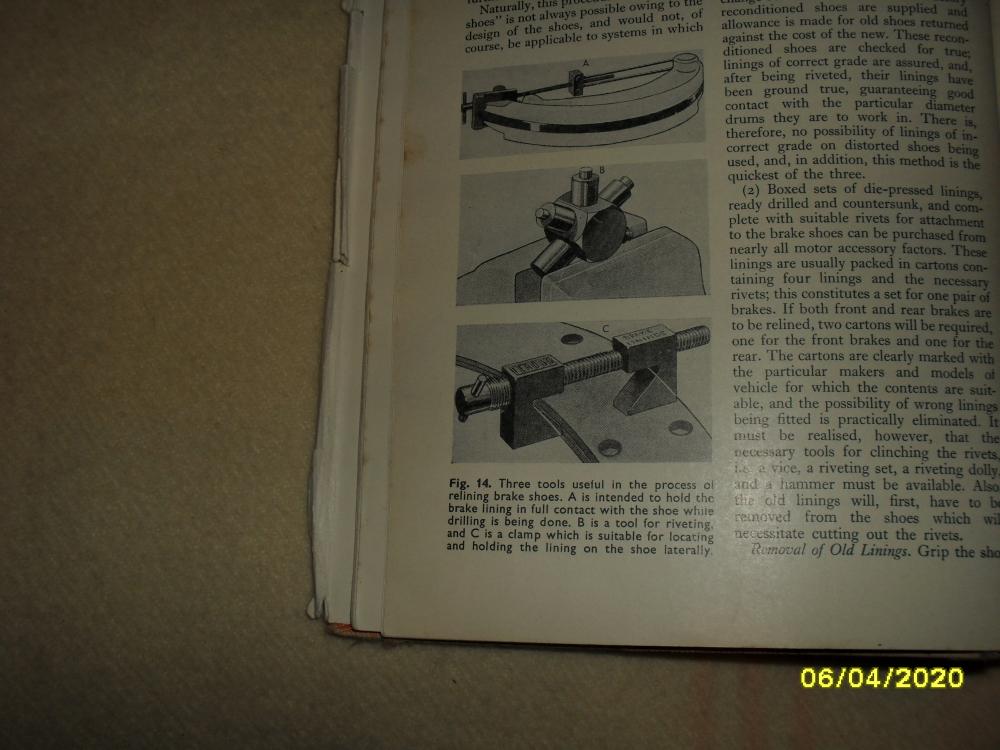

The industry practice at one time was to use a pair of clamps as per 'C' in the attached pic of a page from my trusty

"Practical Automobile Engineering" as the third or fourth pair of hands.

I think one would have trouble finding new ones, but making a pair was a second-year block course exercise in elementary marking out,cutting, drilling threading and filing when I was an apprentice.

The design would have to be modified no doubt to suit the A7 style of shoe but may be of interest to anyone who hasn't seen them before and wants to try their hand at making some. They did work rather well and eliminated a lot of stress and/or bad language.

Note that in the pro version the LH jaw is a clearance fit on the threaded portion and is lightly spring loaded towards the RH jaw. If I recall correctly the apprentice one wasn't and the screw was simply shouldered.

The tee handled screw threads into the RH jaw of course.

If you think it would be of interest, would you mind posting it on my behalf?

Best Regards

AGW"