29-12-2021, 08:51 PM

To all Nippy owners and please anyone knowing a Nippy owner show them this.

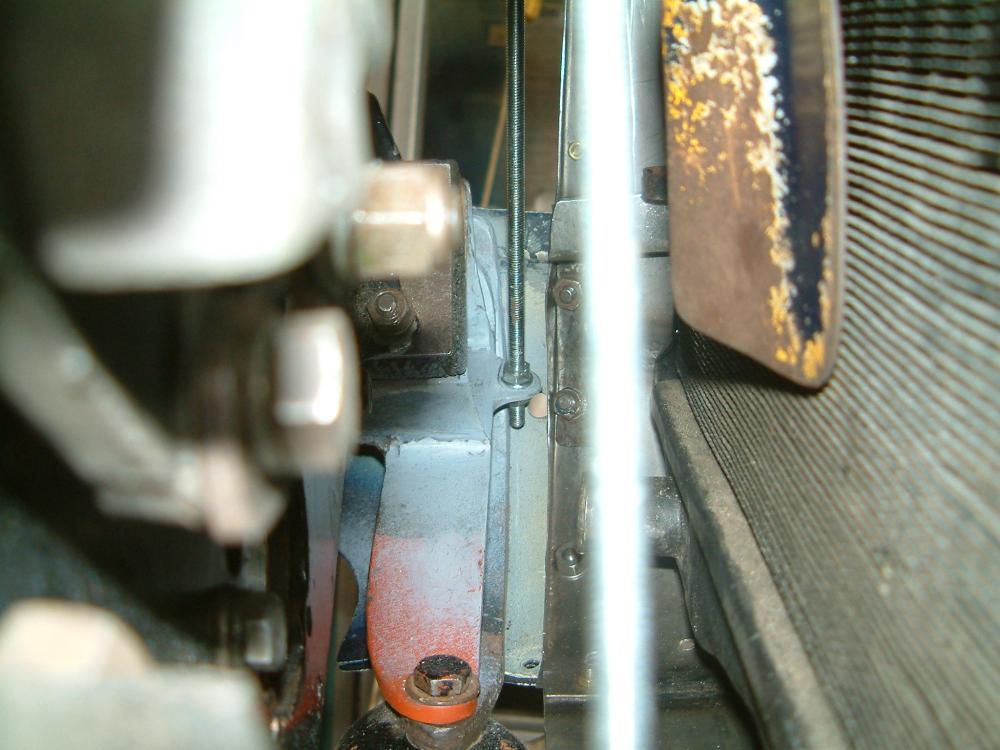

Has anyone else got a Nippy with stays that run from the bulkhead to the top of the radiator cowl/bonnet hinge channel front bracket?

2 lower rods are the stays. Top one is bonnet hinge mount channel.

The radiator ends are individually flattened and fit perfectly together - Ignore the 2 slanted vertical rods.

The bulkhead ends are bent to enter bulkhead at 90 degrees and are just threaded so a nut and large washer is fitted either side of the bulkhead and thus stay length can be adjusted.

The vertical stays (threaded rod allowing adjustable length) are my addition to add extra vertical and side to side support to the cowl/bonnet hinge channel bracket. At top small extensions have been welded to upper rod and small extensions welded to cow horns to provide fixing points.

The radiator is A30 or 35 and hence it does not fit right up to cowl to provide vertical support as would a proper Nippy radiator hence my wanting the extra support.

The bulkhead to cowl rod ends seem to be professional shaped to fit together and were not done by me but are as fitted when I bought. My previous nippy EJ 4322, sold in 1968 to provide money to buy my seagoing uniform, also had those rods. It would seem strange that 2 totally unconnected Nippies would have had 2 owners that made exactly the same rods fitted in exactly the same way/position.

I have yet to find another Nippy with these rods fitted and they are not mentioned in Chris Gould's book and neither had he seen any other one with them (at the last time of talking to him a few years ago).

So Please can anyone solve the mystery of when they were factory fitted (if ever factory fitted) or were these 2 cars just experimental fitted?

Dennis

PS sorry if any purists are offended by the engine. That was my addition....after similar mod to EJ 4322 way back in late 60s inspired after unable to find replacement for broken crank in A7 engine and C.G. telling me about BMC A conversion.

Has anyone else got a Nippy with stays that run from the bulkhead to the top of the radiator cowl/bonnet hinge channel front bracket?

2 lower rods are the stays. Top one is bonnet hinge mount channel.

The radiator ends are individually flattened and fit perfectly together - Ignore the 2 slanted vertical rods.

The bulkhead ends are bent to enter bulkhead at 90 degrees and are just threaded so a nut and large washer is fitted either side of the bulkhead and thus stay length can be adjusted.

The vertical stays (threaded rod allowing adjustable length) are my addition to add extra vertical and side to side support to the cowl/bonnet hinge channel bracket. At top small extensions have been welded to upper rod and small extensions welded to cow horns to provide fixing points.

The radiator is A30 or 35 and hence it does not fit right up to cowl to provide vertical support as would a proper Nippy radiator hence my wanting the extra support.

The bulkhead to cowl rod ends seem to be professional shaped to fit together and were not done by me but are as fitted when I bought. My previous nippy EJ 4322, sold in 1968 to provide money to buy my seagoing uniform, also had those rods. It would seem strange that 2 totally unconnected Nippies would have had 2 owners that made exactly the same rods fitted in exactly the same way/position.

I have yet to find another Nippy with these rods fitted and they are not mentioned in Chris Gould's book and neither had he seen any other one with them (at the last time of talking to him a few years ago).

So Please can anyone solve the mystery of when they were factory fitted (if ever factory fitted) or were these 2 cars just experimental fitted?

Dennis

PS sorry if any purists are offended by the engine. That was my addition....after similar mod to EJ 4322 way back in late 60s inspired after unable to find replacement for broken crank in A7 engine and C.G. telling me about BMC A conversion.

.

. How often do you run your racer with luggage over long distances? My first Nippy (road going only) had the Bowden twin spring IFS (Made in Devon)....transformed the handling to make driving it a more pleasurable experience.

How often do you run your racer with luggage over long distances? My first Nippy (road going only) had the Bowden twin spring IFS (Made in Devon)....transformed the handling to make driving it a more pleasurable experience.